“ALCERA“ 1720 ℃ high temperature furnace

Institute of the high temperature furnace for my company to give a research and development of special high temperature furnace, use for sapphire, annealing, due to the process requirement, the furnace to meet the long-term working temperature 1720 ℃, customer demands for 2 weeks, 1720 ℃ heat preservation 2 weeks, the thermal insulation material and heating elements, high temperature kiln furniture, thermocouple is a major test, through the efforts of our technical staff, finish delivery of equipment, and so far the use time has reached a year and a half time, equipment operation condition is good, stable performance.

The equipment adopts full fiber thermal insulation structure, excellent into the exhaust system, ensure the service life of furnace at the same time, greatly saving energy consumption, reduce customer sintering cost, we have received mass production of customer orders.

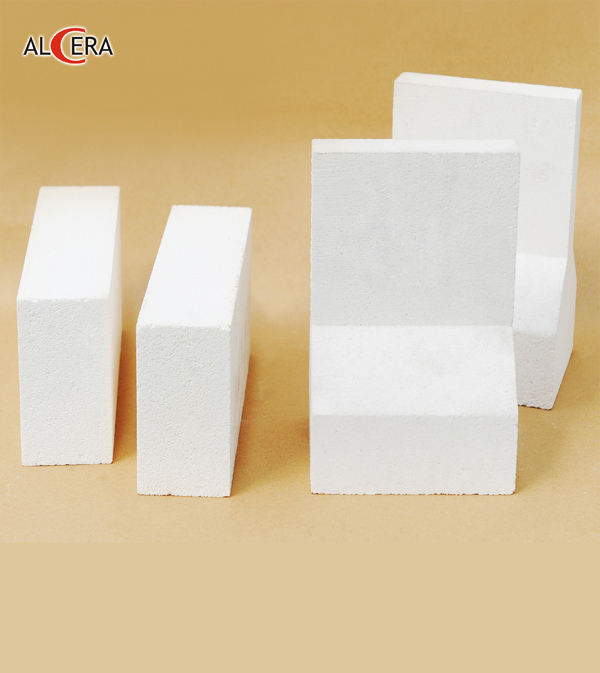

Al is committed to high-end refractory insulation materials research and development production, at present, the company's main lightweight insulation materials, all kinds of high temperature furnace, high temperature kiln furniture, welcome to order

“推荐阅读”

- Why first use of ceramic fiber textile will turn black?

- Why the electric furnace internal severe crack in the wall part?

- Why a circle appears on the furnace door, and black?

- The chamber of a stove or furnace wall crack, how to deal with?

- High temperature industrial furnace heat insulating varnish insulation effect

- The chemical reaction principle of the experimental furnace gasification stage

- In today's society is analysed high performance refractories greater development potential

- Science and technology innovation to accelerate the development of refractory industry

- The selection of insulating refractory application in metallurgical industry

- ALCERA - high-end thermal insulation material manufacturers

【责任编辑】:ALCERA版权所有:http://www.alcera.cc转载请注明出处